Tooling

Injection Mold Building, Production, and Prototyping

Experienced, quality workmanship meets efficiency

A company originally founded on mold building services, Reed City Group is uniquely equipped to build high quality, precision molds for a nearly limitless spectrum of injection molded plastic parts. We specialize in high quality plastic injection mold building, with on-time deliveries. Our team of mold makers and machinists are highly skilled in the entire production process, from mold design to full tryout and in-house sampling. We maintain superior workmanship and attention to detail, and our processes combine old-world craftsmanship with the latest machining technology.

We also provide responsive, professional service, from the initial design concept to long after the mold has been in service. Our Project Engineers have strong backgrounds in machining, mold making, automotive markets and the injection molding process, so they have the experience to give customers exactly what they need. Projects run smoothly at Reed City Group. Our Sales Program Managers streamline customer requests and ensure specifications are clearly understood by the mold build department. Jobs are carefully tracked and timelines are kept, ensuring projects are completed on time and on budget. After the project is complete, our team provides responsive repair and support. Plus, emergency repair service is available for all tooling customers 24/7.

Let our team work with you to design and build the right mold for your project.

- Prototype and production injection molds

- 2 shot production molds

- Gas-assist automotive door handle tooling

- LCC landing capabilities or combo molds

- Embossing dies

- Conformal cooling inserts

- Additive manufacturing prototyping available

- Quick-turn engineering changes

- Emergency mold repair

- In-house tool maintenance for production molds

Laser Welder

Precision Mold Building for Tier 1 Brands

Reed City Group’s skilled journeymen have crafted molds for some of the top names in the auto, medical, and consumer industries. From Cadillac grills to Rainbow vacuum cleaners, our mold engineers and quality assurance team build molds that make successful products. We’ve built molds for most industries, and over the years we’ve specialized in:

- Tier 1 and 2 automotive

- Medical industry

- Consumer products

- Pharmaceutical

Some of our biggest successes have been building molds for key high-end automotive components, but our precision tooling expertise has also been valuable in consumer and medical applications. Our in-house sampling, dimensional accuracy and on-time delivery help manufacturers in these competitive markets.

2- shot Production Mold Manufacturing

Reed City Group handles a wide range of mold manufacturing complexities, including 2 shot molds. Our 2 shot molds will improve your efficiency, lower your per unit cost, reduce waste and scrap, improve aesthetics and ergonomics, and allow for increase complexity in design. Contact us today to learn more about our 2 shot mold manufacturing capabilities.

Emergency Mold Repair and Ongoing Maintenance Programs

When injection molds break down, production stops — and so does profitability. At Reed City Group, we stand behind every mold we build. We also provide around the clock emergency mold repair service, on any mold in your facility. Our team of mold experts is available to provide repairs for each and every one of our customers.

To prevent production failure and unforeseen downtime before it occurs, our mold repair team also provides services for engineering changes, preventive maintenance and routine repairs. Regular inspection and thoughtful planning ensure minimum downtimes and maximum profitability.

To schedule mold repair or maintenance, please call your dedicated sales engineer or program manager at 231.832.7500.

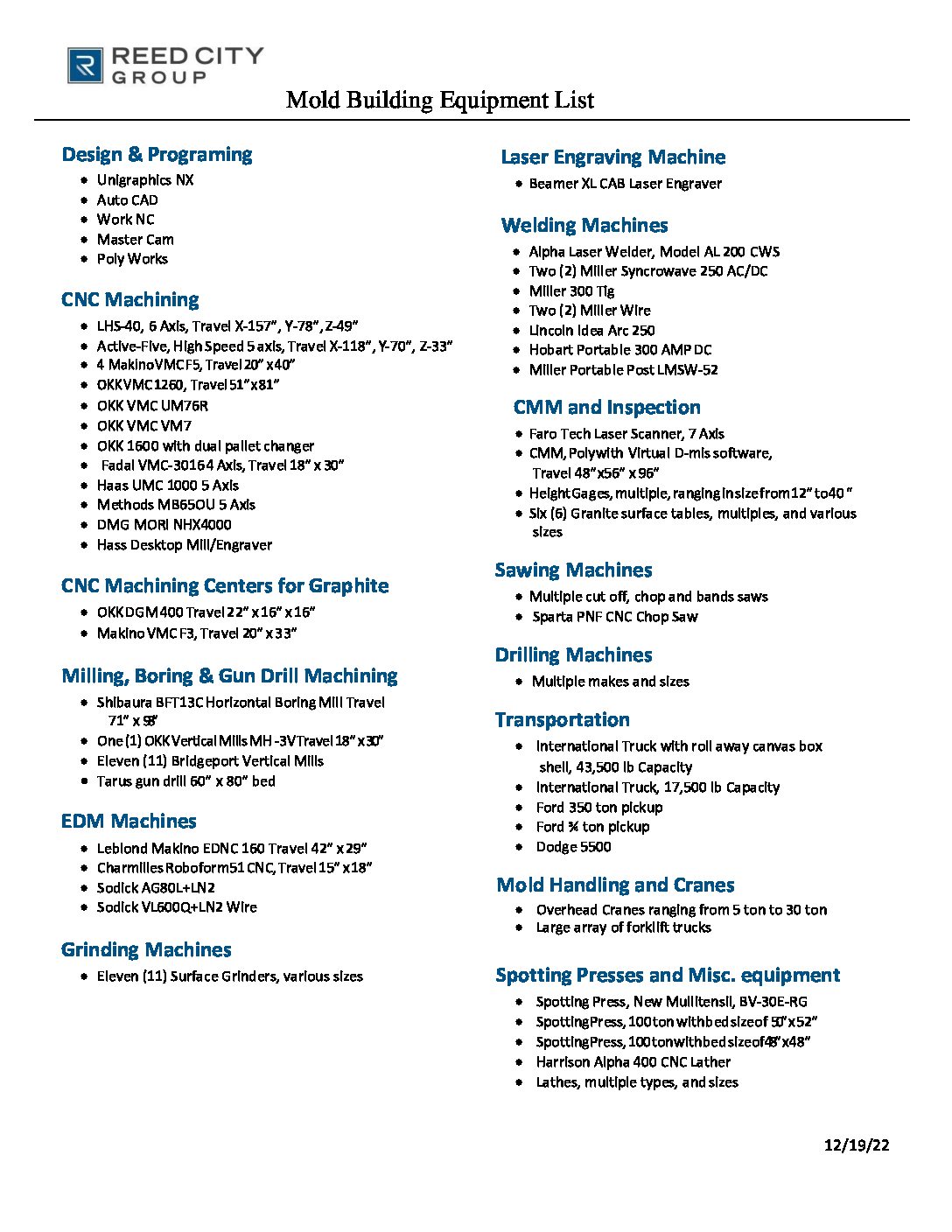

Click the image to the right for our current equipment list, or request one at 231.832.7500, or info@reedcitygroup.com

Tool machining size restrictions are also limited to 50″ by 80″.

Streamlined Systems for Mold, Part, and Press Manufacturing

In addition to our team’s expertise in skilled trades, Reed City Group provides a streamlined system for program management. A dedicated team of these industry-vetted Sales Program Managers walks our customers through each step of the mold, product or press manufacturing process. From quoting and concepting through design and build, a dedicated expert manages each account from start to finish.

When working with us, there’s no need to coordinate with and track down personnel in various departments. Sales Program Managers are a customer’s first and last contact for each project, and they provide regular communication between the customer and our design and build departments to make sure each project is delivered precisely to its specifications, on time.

Meet our Program Management Team:

Mark Blume Director of Business Development (Automation)

Mike Seay Senior Program Manager

Matt Walcott Senior Program Manager/Design Manager

Jeb Callaghan Program Manager

Shawn Ward Program Manager (Life Sciences)

Bryan Cassiday Program Manager (Life Sciences)

Chris Barton Commercial Manager

John Konieczny Program Manager

Jon Hooker Program Manager (Life Sciences)

Ray Nixon Electrical Applications Engineer (Automation Equipment and PLC Panels/Enclosures)